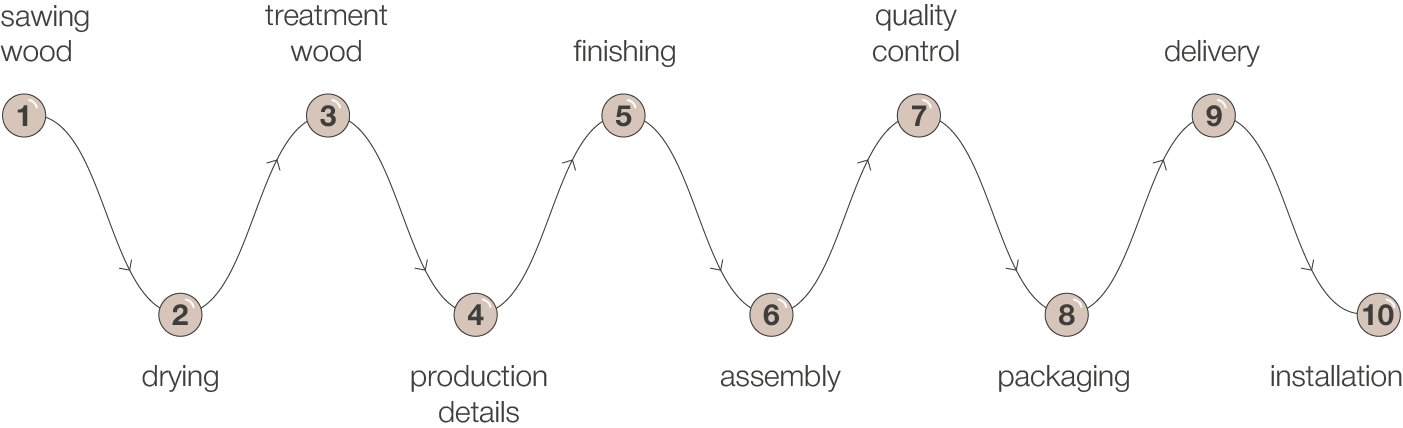

Manufacturing process at our company

at our company

In order to facilitate installation, we pre-assemble our furniture:

- cabinet carcasses come pre-assembled;

- cornices and plinths require minimum adjustment;

-pre-drilling for easy hardware installation.

- cabinet carcasses come pre-assembled;

- cornices and plinths require minimum adjustment;

-pre-drilling for easy hardware installation.

30 years

Experience

Experience

over 190

Employees

Employees

Sawing timber

We have our own sawing machines. . We do not buy lumber, instead we process wood according to our specific needs and requirements.

On-site

sawing

sawing

=

reduced

costs

costs

We dry wood at the factory. We use INCOPLAN wood drying equipment for high quality drying, which guarantees our furniture will look unchanged and function properly for many years. The multistage drying process brings the moisture content to the optimum without swelling or cracking.

7-9%

moisture content in the wood

moisture content in the wood

Up to 30 days

wood drying

wood drying

140 cubic meters

volume of wood dryer loading

volume of wood dryer loading

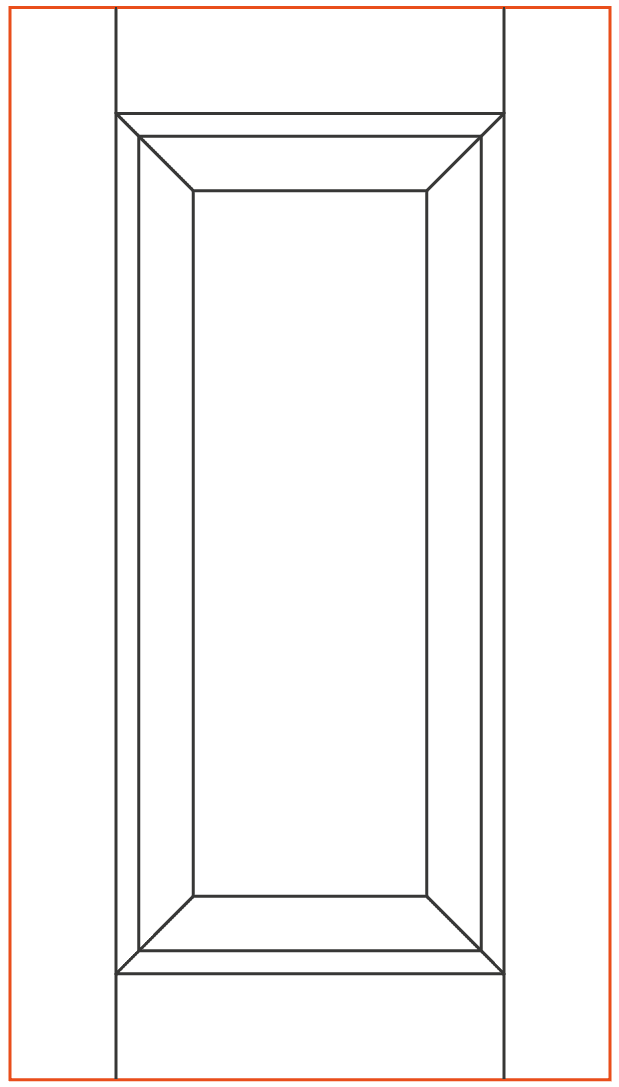

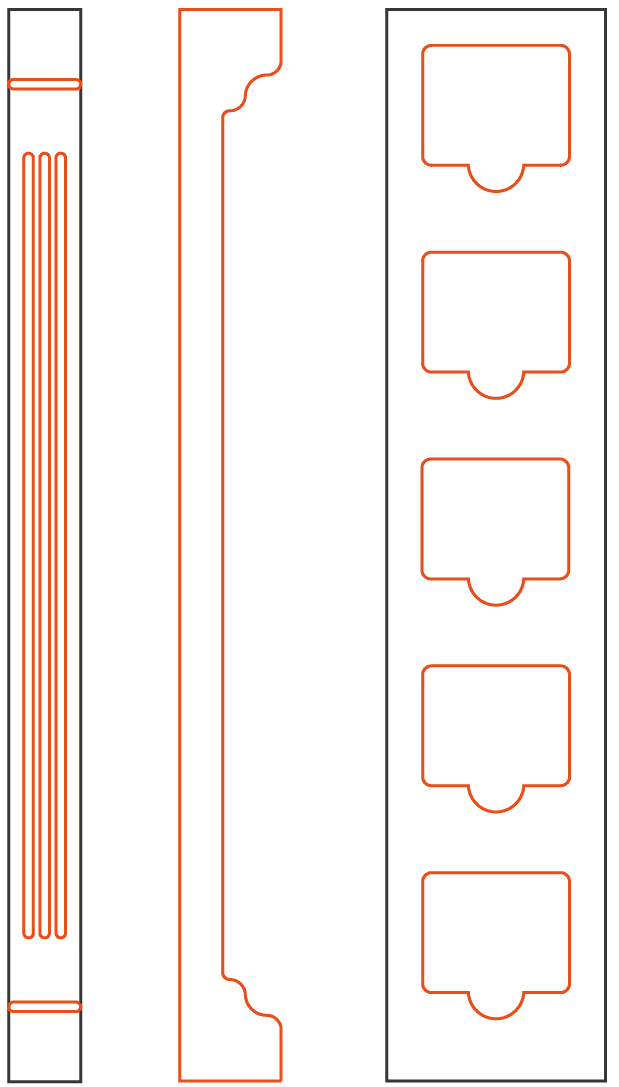

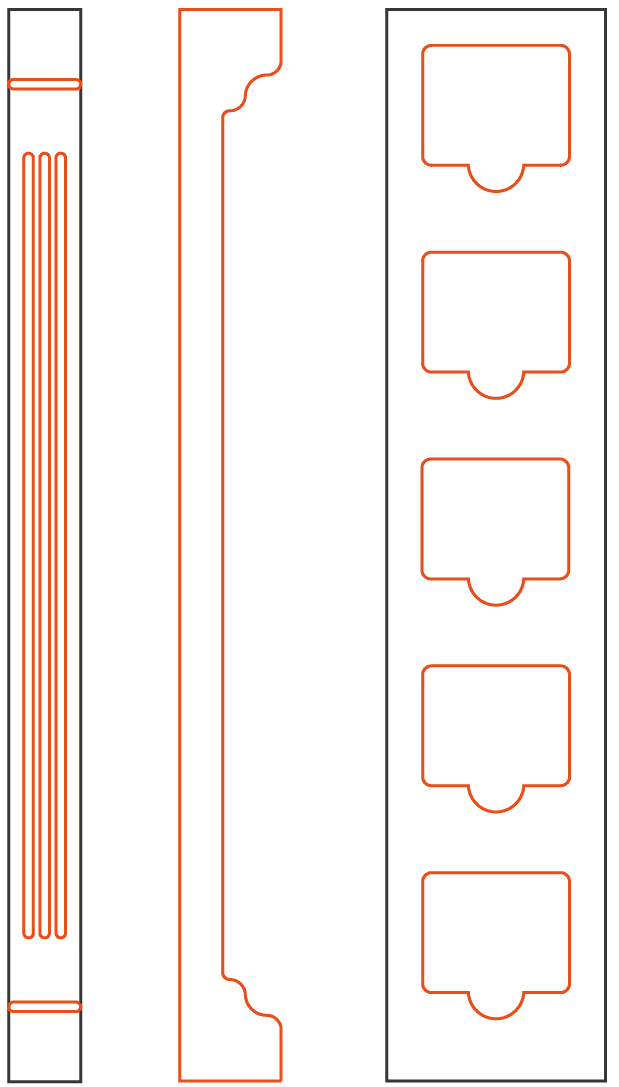

Milling

We have

several CNC processing centers made by Biesse, Italy. We use them to perform computer-controlled drilling and shaping operations with extreme precision.

Door edge

processing

Geometric accuracy of machined elements - up to 0.1 mm

processing

Geometric accuracy of machined elements - up to 0.1 mm

Milling decorative

elements

curvilinear parts, pilasters, etc

elements

curvilinear parts, pilasters, etc

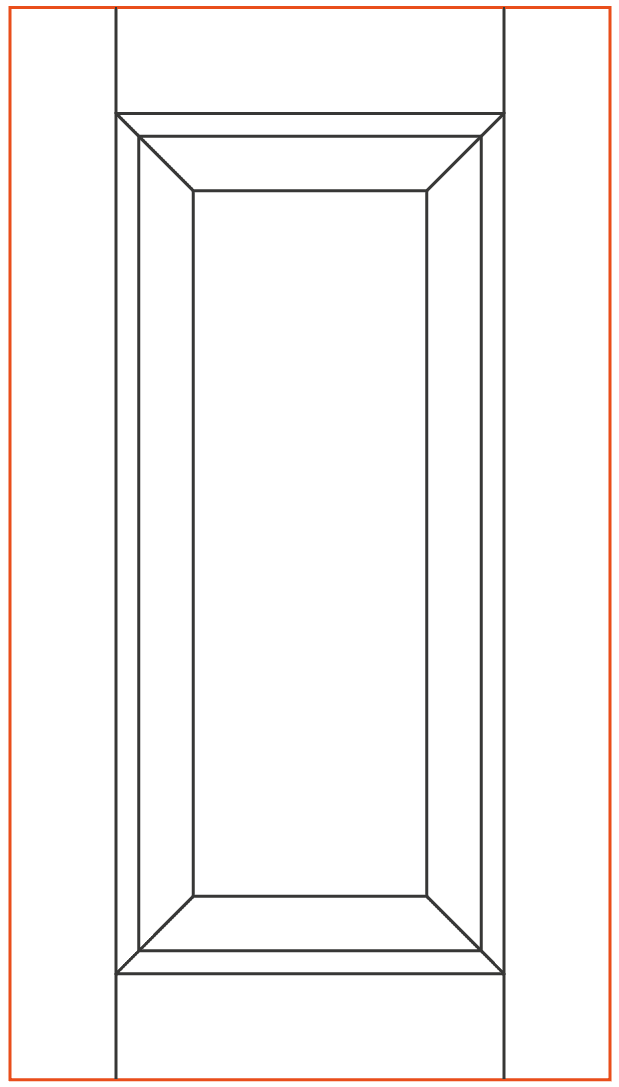

Nesting and cutting flat material

In order to make cabinet panels and slab doors, we cut laminate, Wood veneer, MDF, plastic and acrylic flat material by means

of Selco cutting machines from Biesse, Italy.

Automated material processing

reduced operating time; accurate dimensioning - accurate assembly

Optimum nesting

reduced costs of end products

1

Automated material processing

reduced operating time; accurate dimensioning - accurate assembly

2

Optimum nesting

reduced costs of end products

Laser edge banding а

We use the HOLZ-HER and Brand edge banding machines made in Germany. The adhesive-free two-layer edge band is heated by hot air, or laser. Then it is pressed firmly to the panel to create a permanent, seam-free bond between the edge band and the substrate.

Cabinet door

Cabinet door

Water-proof laser edge banding .

Carcass

Carcass

Water-proof edge banding with PUR adhesive .

Cabinet door

Cabinet door

Water-proof laser edge banding .

Carcass

Carcass

Water-proof edge banding with PUR adhesive .

LASER

EDGE BAND

EDGE BAND

=

INVISIBLE

BONDLINE

BONDLINE

“Clean room”

We use Italy’s Tecno Azzurra pressurized painting rooms with a water filtering system :

1

Perfect

surface

no specks of dust or grainy surface

surface

no specks of dust or grainy surface

2

Eco-friendly

technologies

reduced emission of harmful substances

technologies

reduced emission of harmful substances

3

Comfortable

working conditions

Little harm for personnel

working conditions

Little harm for personnel

4

Increased

productivity

reduced costs of end products

productivity

reduced costs of end products