Laminated chipboard

In the budget kitchens of the GeosIdeal factory, front elements can be made of laminated chipboard.

The first prototype of a modern plate was presented to the scientific community by the Swiss Ernst Hubbard back in 1887. The main task was to replace expensive solid wood with cheaper material and to use waste from the woodworking industry efficiently.

For 130 years, the manufacturing technology of laminated chipboard has been improved, turning this plate into the main material for the production of panel furniture elements.

The basis of laminated chipboard is 3 layers of sawdust of different size fractions and densities (the outer layers are denser, the middle layer is less dense), pressed at high temperatures (180-220 ° C) with the addition of thermosetting synthetic resin as a binder.

Further, the already cooled plate is lined with a paper-laminated material impregnated with melamine resins. A relief texture is pressed on its surface.

The embossing on the surface of the plate repeats the pattern of the decorative layer, which makes it possible to achieve a unique natural effect: the surface of the material, both visually and to the touch, is almost impossible to distinguish from natural veneer, wood, fabric, stone or plaster.

Chipboard quality parameters:

- the density of the base and the “correct” arrangement of sawdust. The factory uses the highest quality laminated chipboard – with density values from 625 kg/m3 and above.

- formaldehyde emission class – safety indicator. In the production of GeosIdeal furniture, laminated chipboard is used, which meets the most stringent standards – E 0.5 and E1. The additional guarantee is the gluing of the ends of the parts with an edge tape using PUR technology, which ensures a tight fit of the edge to the base and “sealing” of pores on the surface of the chipboard.

- The thickness of the decorative composite-laminated material is an indicator of wear resistance. Surfaces with thicker decors (Syncron, Egger brands) are similar in properties to various types of plastic.

Advantages of chipboard:

- Manufacturability. It is convenient to work with the material and carry out all technological operations: cutting, joining, pasting, etc.

- Durability. Throughout the entire service life, the plate retains its appearance (does not dry out, does not twist). The color retains its brightness and depth, regardless of the intensity of cleaning and UV exposure.

- Large selection of colors: textural decor (stone, quartz, leather, marble, etc.); plain (sand, milk, cream, and other shades); wood imitation (oak, pear, ash, etc.).

- Practicality. For the care of finished products, standard household chemicals are used, with the exception of abrasives and solvents.

- Lower price relative to solid wood and MDF

Features of chipboard:

- The material is less durable than solid wood.

- Limited moisture resistance. This shortcoming can be compensated by high-quality pasting (PUR-technologies, laser edge) of all cut surfaces.

- The binder resins used in its production emit formaldehyde harmful to humans. For the manufacture of furniture, chipboard with an emission class of harmful substances E1 and below is used. Pasting the ends of the front and body parts made of chipboard with edge tape reduces emissions to a minimum.

For the production of chipboard fronts, the GeosIdeal factory uses products from well-known European brands Syncron, Egger

Syncron (Alvic Grupo, Spain)

The Spanish manufacturer of premium font and board materials Alvic Grupo offers structured panels of the Syncron line. Fronts for kitchens and other types of furniture made of structured Syncron panels create a full-fledged feeling of natural material – their surface is not flat, but follows the structure of wood, stone or cement (depending on the type of decor).

Alvic Syncron decorative structured panels are designed to become a more technologically advanced and high-quality alternative to natural materials. The ends of the panels are closed with an ABS edging from the Portuguese manufacturer Probos, which completely merges with the surface of the plate, having an identical color and structure.

Advantages of Syncron panels

- realistic textures

- strength and durability of the coating

- ease of care. Even plates with the deepest structure are easy to clean with the correct cleaner(do not use solvents, abrasive or acid-base products, and steam)

- bilateral lamination. The reverse side of the door is finished with a smooth laminated film in the color of the front panel

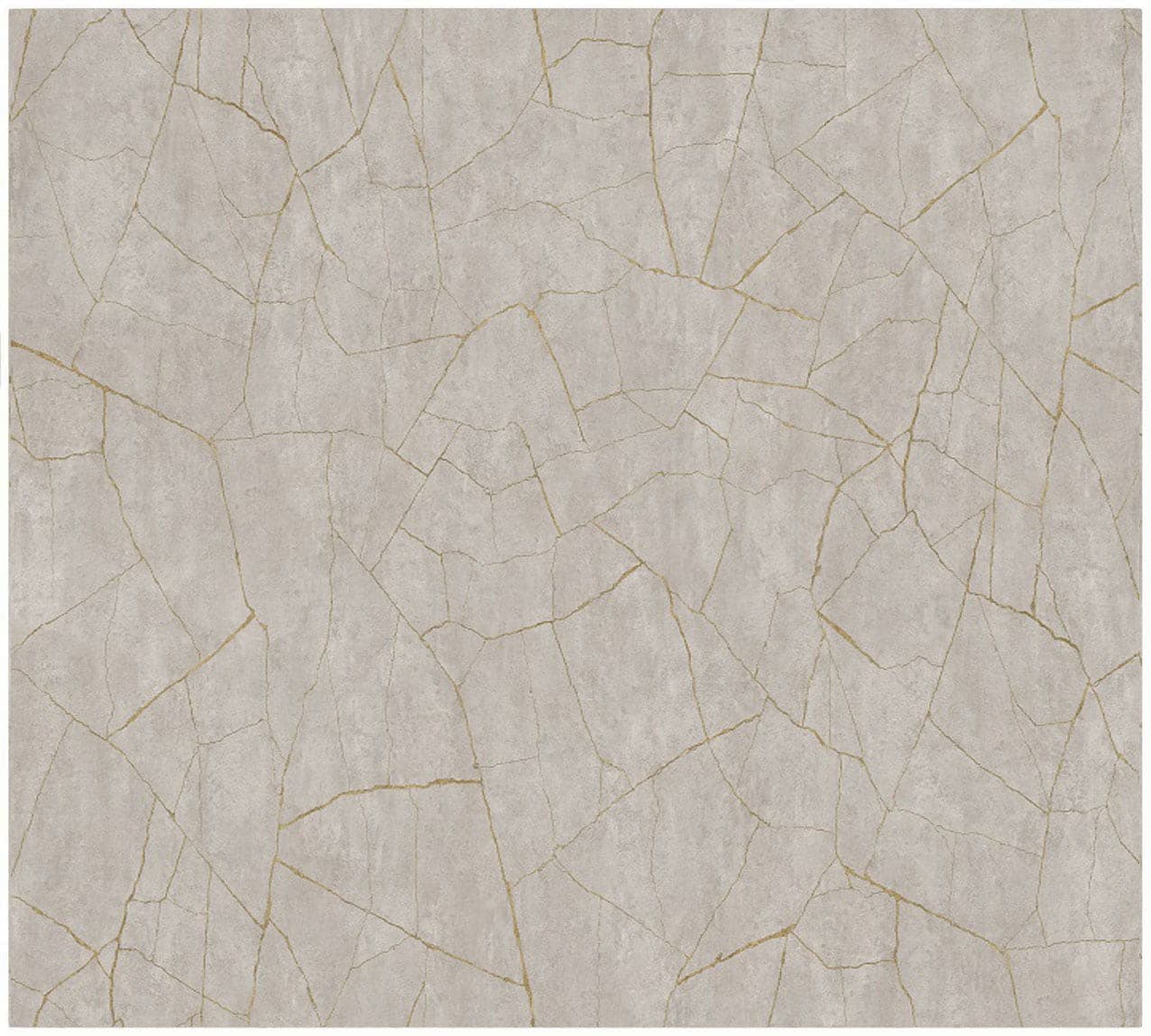

Porchelain 01

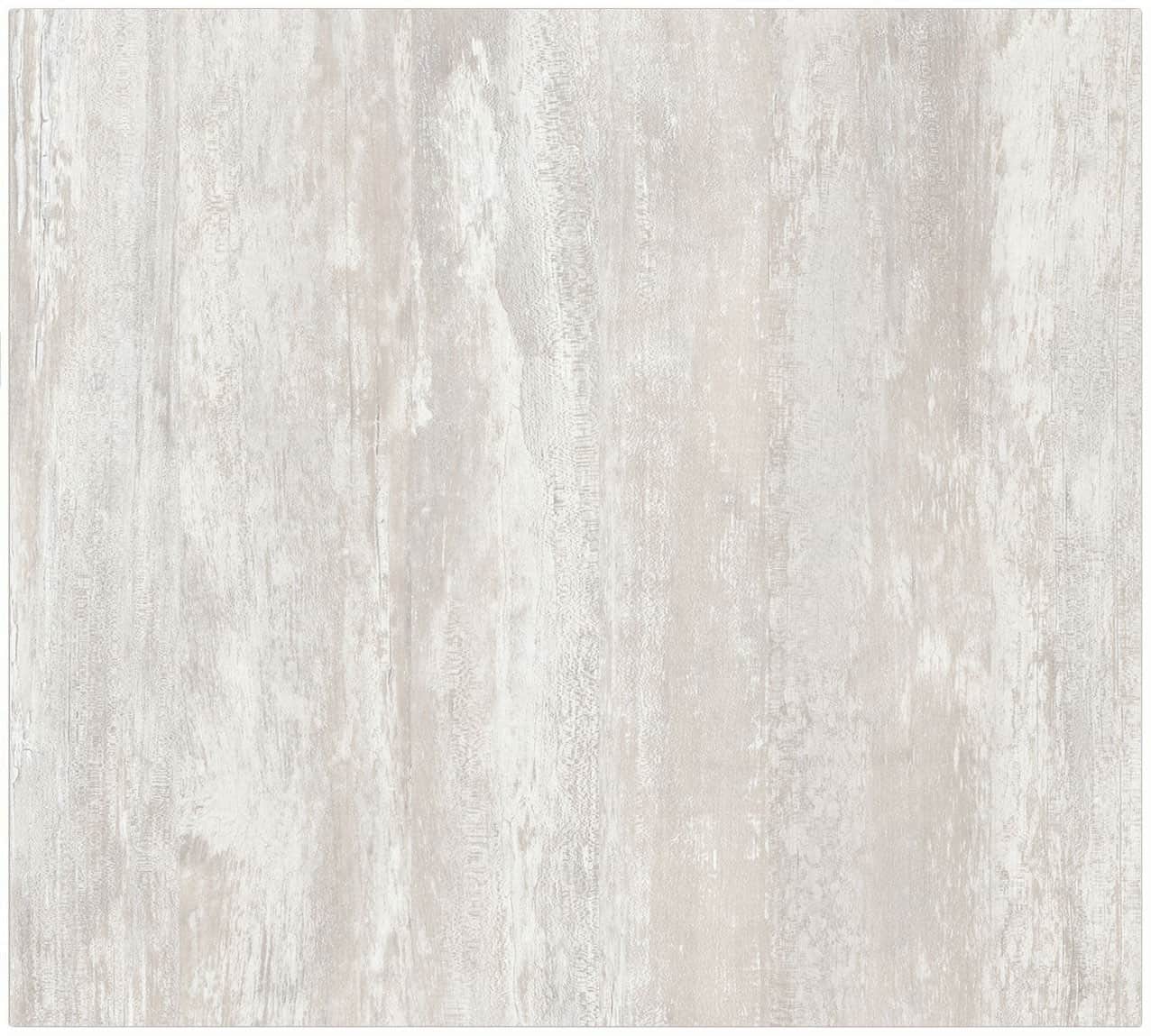

Ice Cream 001

Evora 004

Egger (Austria)

Kitchen Eywa, Egger, Natural Hickory

The Egger group of woodworking companies, headquartered in St. Johann (Austria), includes 18 factories for the production of various board materials. They are located in Europe, Asia and America. Chipboard produced under this brand has a number of characteristics that determine its high popularity among furniture makers all over the world.

- high quality plate surface

- hygiene safety

- a rich selection of realistic decors imitating wood, stone and other natural materials

- expressiveness, depth of relief and naturalness of texture the surface of Egger chipboard is as close as possible to natural samples

- an affordable price that allows using Egger laminated chipboard for the production of not only fonts, but also furniture cases for various purposes

Natural Hickory

Kaszina Pine

Textile beige

Kitchens with laminate fronts combine high functionality and quality of all components with a design that reflects modern stylistic trends. An important parameter is the relatively low price of laminated chipboard kitchens.