Solid wood

Every employee of the GeosIdeal factory can tell a lot about wood, because, despite the variety of new materials, wood has been our main specialty for over 30 years. The technologies of working with wood have been time-tested, the stylistic solutions of the models have been perfectly worked out. Therefore, if you decide to buy kitchen with solid wood fronts, it should be the GeosIdeal kitchen. And if you have not yet chosen the kitchen material, read this article.

Wood is the oldest material for furniture production, characterized by manufacturability, strength and high decorative effect. The pattern of its texture is always unique, so every kitchen set made of wood is inimitable. Even if your neighbor has a kitchen model similar to yours, you can be sure that the kitchens will be different.

Advantages of solid wood:

- Decorative. The wood grain pattern is font important element that forms the look of the kitchen, it is already beautiful in itself, and with additional author’s finishing it is unique.

- Durability. The wood of oak, ash and other valuable species is very hard and practically is not damaged during operation.

- Longevity. A kitchen made of wood does not become outdated for many years either morally or physically. Small damages that occur during its operation have practically no effect on the appearance of the kitchen. Bigger damage can be easily repaired.

- Practicality. Wooden furniture is easy to clean. Minor damages on its fronts are not striking, and the eternal problem of “fingerprints” worries its owners much less than the owners of a plastic kitchen.

- Environmental friendliness. Wood is a natural material. In the production, operation and recycling of kitchens minimum harmful substances appears.

- Relaxing effect. The unique wooden pattern, pleasant tactile sensations from touching the wooden fronts have a beneficial effect on the mood of the mistress, and therefore her entire family.

- Status. Owning a kitchen made of wood is a sign of success in everything. Even a budget kitchen, but made of wood, looks respectable and characterizes its owner as a person who appreciates quality and can afford a lot.

Peculiarities of solid wood furniture:

- Price. Yes, solid wood kitchens are more expensive than chipboard kitchens. But, if you plan to use the kitchen for more than 5 years, your additional costs will be justified.

- Sensitivity to changes in temperature and humidity. For a long and trouble-free operation of the kitchen, the same microclimate in the room is required, as recommended for humans, namely: temperature – 20-24 ° C, relative humidity 45-65%.

Front elements made of solid wood can react to changes in air humidity, slightly changing their dimensions. To reduce this effect, the surface of wooden elements is covered with several layers of paints and varnishes. In addition, there are many ways to adjust the temperature and humidity of the air (humidifiers, etc.) in the room. Thus, the microclimate in the room will always remain comfortable for furniture and for people.

In most cases, changes in the geometric dimensions of wooden facade elements are reversible: after the restoration of the recommended humidity in the room (45-65%), they return to their original state.

Solid oak

Wood hardness - 3.7 kgf/mm² (Brinell scale) or 1290 lbf (Yanka scale) Wood density – 700 kg/m³

Calm drawing, slight color differences

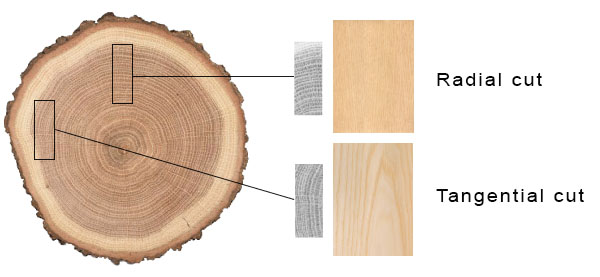

- Radial cut. Almost parallel narrow dark lines are obtained with a radial cut, when the plane of the cut is perpendicular to the growth rings. Such a pattern is sometimes called “calm”.

- Tangential cut. A very decorative texture pattern in the form of wavy and arcuate stripes of very different orientations. It is formed when the cut plane passes tangentially to the growth rings.

In the production of the front, lamellas of tangential and radial cuts are combined.

Sometimes light shiny stripes are visible on the plane of the front. These are core rays, which are an element of the structure of a tree trunk and appear on the surface with a certain sawing direction.

Note: Oak wood is more calm in color transitions, so oak is used for the manufacture of fronts with a transparent finish.

Solid ash

Wood hardness - 4.0 kgf/mm² (Brinell scale) or 1320 lbf (Yanka scale) Wood density – 690 kg/m³

Decorative, contrasting pattern

Ash wood is not inferior in hardness and density to oak, and even surpasses it in decorativeness. The texture pattern is also “calm” (radial cut) and “wavy” (tangential cut). It is ash that has the most beautiful wavy texture, which is romantically called “tongues of flame”.

A feature of ash wood is a wide range of changes in its main color (from light cream to brown) – fronts made from different parts of the trunk can differ markedly from each other in tone. Completing solid-colored ash front elements is a difficult task, so they are covered with opaque paints. In this case, patination is used to emphasize the beauty of the wood texture – filling the previously worked out pores on the surface of the front (“brushing”) with special paint (patina). Applying a patina is a painstaking manual work that requires high professional training.

What to choose: oak or ash?

From all of the above, an unambiguous conclusion follows – oak and ash are not inferior to each other in hardness, which means that you need to trust only your aesthetic preferences. The operational properties of solid oak or ash wood are absolutely identical. Choose a kitchen model from an array that will please your eye and cheer you up for many years!

Note: All wood comes to the factory from its own logging site. Its characteristics meet the most stringent hygienic requirements. According to a specially developed program (15-35 days, depending on the type of wood), the moisture content of wood is brought to values on modern drying equipment that guarantee the stability of the dimensions and shape of the front elements during the subsequent operation of the kitchen