About factory

Market leader

Established in 1991, GEOSIDEAL kitchen factory now takes one of the leading positions in the kitchen furniture market in Belarus.

For more than 30 years, customers have preferred GEOSIDEAL, a brand with a pronounced personality. We want the kitchen to be not only comfortable and high-quality furniture for cooking, but also to become a favorite place where the soul lives, where you want to be and enjoy..

When choosing the best materials in each price segment, we offer unique design solutions for the kitchen, living room, hallway or bedroom. Customized furniture can be either of standard sizes or non-standard, i.e. fully integrated into the room; can be made from both cost-effective laminated chipboard and from a designed solid wood; equipped with high-quality fittings of various price levels. The products created by a team of professionals always reflect the main values of the company.

Company values

GEOSIDEAL as a family company with a long tradition, follows the basic ethical principles in its activities, such as respect for customers, partners and employees.

Experience

Perfectionism

Temperate design

Ethical principles

Trust and respect

GEOSIDEAL now

GEOSIDEAL has gone from a small enterprise producing solid wood furniture to a modern high-tech factory.

130

studios in 5 countries

180

finishes and materials

190

employees

10 000

units and cabinets

12 000 м2

sqr.m. production area

While being a full-cycle furniture production, GEOSIDEAL factory consists of 8 divisions:

own wood procurement workshop

industrial wood drying workshop

production of fronts from solid wood and MDF

production of carcasses and fronts from panel materials

transport and logistics center

design department

main office

kitchen studios chain

More than 190 employees

More than 190 employees from Minsk, Brest, Zhitkovichi and Smolevichi apply their efforts and skills to bring new furniture into your home. The work of each of them is very valuable to us.

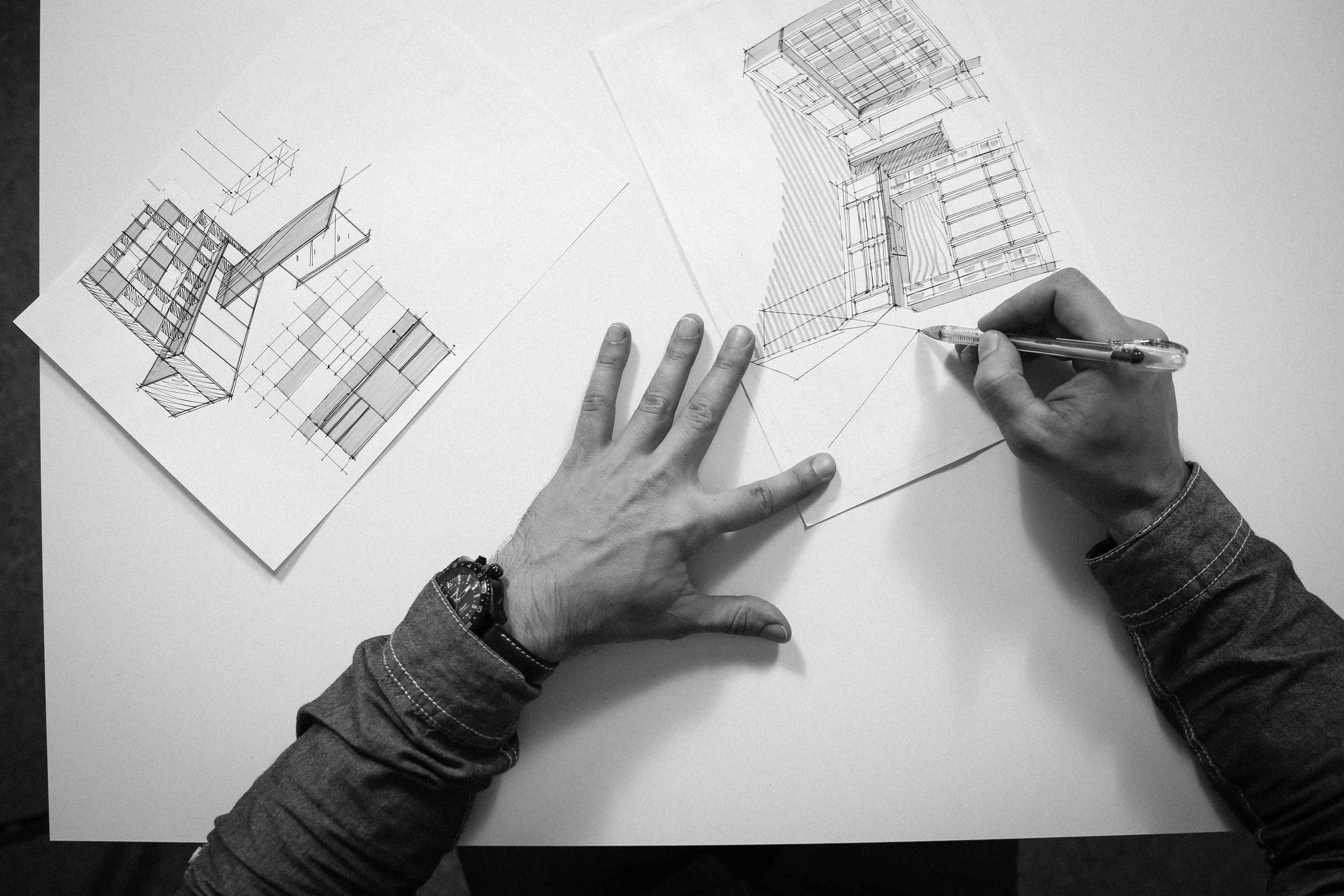

The average production time for a kitchen is 30 days. However, it is born even earlier – at the stage of the idea or image of the model.

The development of a kitchen model is a painstaking work and a very exciting period, which normally takes from 6 to 12 months. Global design trends, modern technology, local traditions, innovation, marketing demands and manufacturing capabilities are all taken into account when developing a new model. The details are carefully worked out to create an almost complete image. When choosing your kitchen in the kitchen studio, you are personalizing the design idea, adapting it to your own tasks. The studio assistant helps to build the kitchen organically. And then your kitchen goes to the production in the form of a placed order.

Partners

In order for the furniture to serve for more than 20 years, the factory carries out a careful selection of materials and components it is made from. These are the leading European manufacturers of fittings, components, laminated chipboard and paints and varnishes.

No defects

In addition to the incoming control at the warehouse, the quality of all elements is checked at all stages of furniture production.

The final assembly of the kitchen modules is decisive. It guarantees the completeness of the order and the absence of any defects.

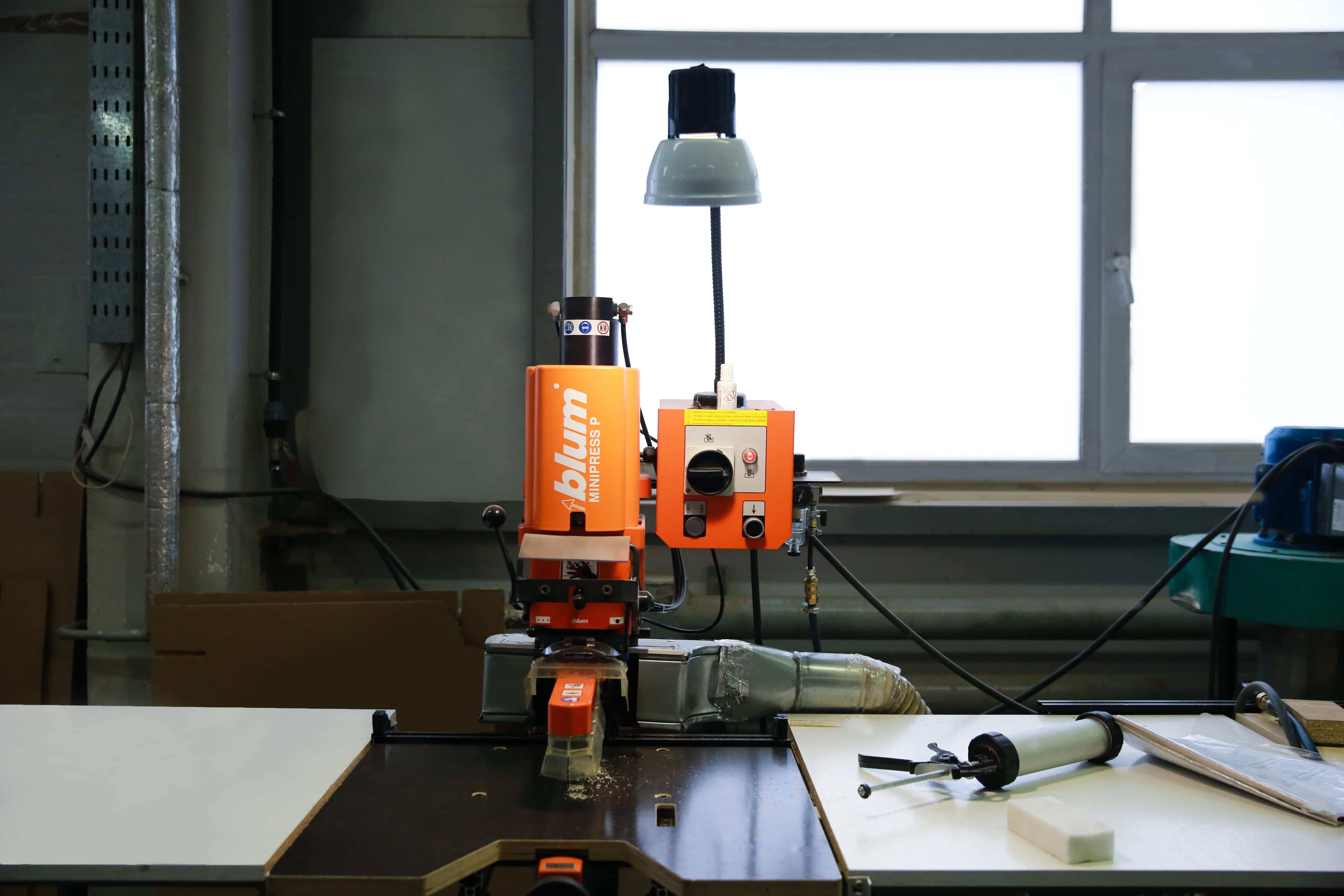

The high quality of GEOSIDEAL furniture produced at relatively low prices is explained by using of modern equipment at all stages of its manufacture.

Thus, the hydrothermal processing of wood is carried out in drying machines Incoplan (Italy) with automated humidity and temperature control. It evens out the moisture content of the solid wood, relieves it of internal stress and cracks.

Edge banding and veneer gluing is performed on a high-performance machine Holzher Lumina (Germany). Edging is carried out using an infrared ray in two versions: using PUR technology and using a laser edge. This allows a 100% adhesion of the edging tape to be obtained without a glue seam.

Painting of wooden and veneered parts takes place in a high-tech spray booth with multi-level dust protection and a deep air purification system.

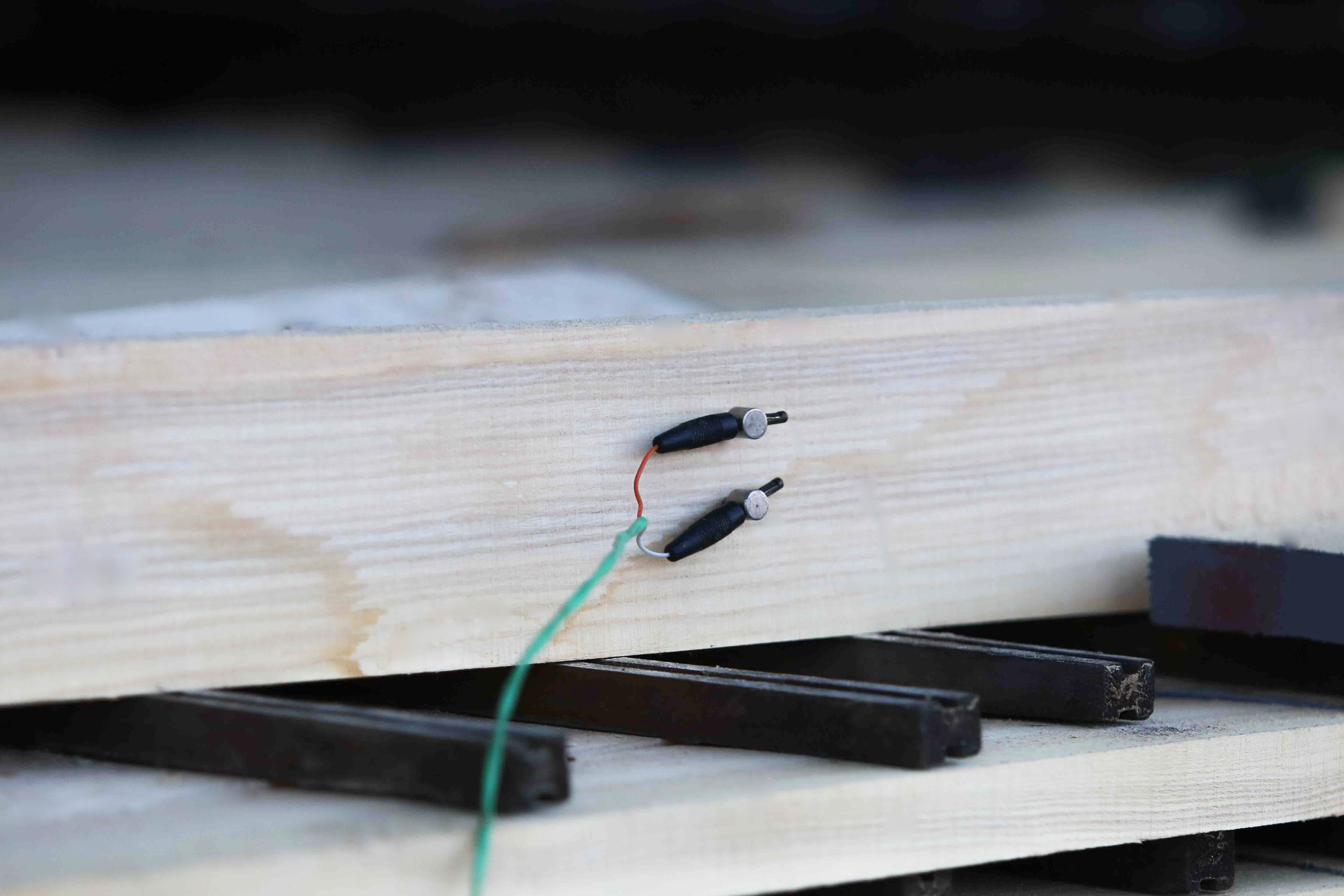

Manual labor

Modern technologies and materials used in the production of GEOSIDEAL kitchens do not exclude elements of manual work of cabinetmakers. Wood carving, filigree sanding, assembling, patina and topcoating are just a few of the manual operations. A professional team of carpenters, thanks to their painstaking work, create unique pieces of furniture. This is the real value of the company.

Special packaging (including a 5-level system for protecting facades from damage), developed at the factory, ensures the safety of furniture during transportation.

So, GEOSIDEAL furniture, having come a long way from the designer’s idea to installation, ends up in your home. We are sure that our painstaking work, embodied in a unique product, will become a real stimulus for culinary creativity, surround you with a soft atmosphere of “home”, and most importantly – it will delight you for many years!